Hydraulic press machines play a critical role in a range of industries, from automotive to aerospace, metallurgy, and more. They enable the shaping and forming of materials with precision, accuracy, and efficiency. Given their importance, it’s crucial to partner with a reliable manufacturer when sourcing these machines. Here are the key qualities that a reputable hydraulic press machine manufacturer should embody:

Robust Quality Control

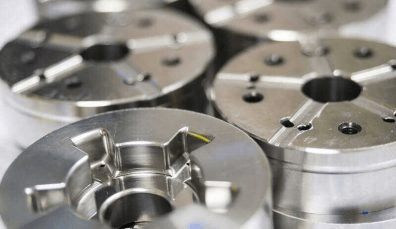

Every hydraulic press produced should undergo rigorous quality checks. This ensures that the machine meets the established standards and will operate optimally in the field. A trustworthy manufacturer will prioritize quality control, employing state-of-the-art testing techniques and equipment.

Expertise and Experience

Years in the industry matter. A manufacturer with a history of producing hydraulic presses will have encountered and resolved various challenges over time, refining their products and processes along the way.

Cutting-Edge Technology

The world of hydraulic presses isn’t static. New technologies and innovations emerge regularly, aiming to improve efficiency, safety, and functionality. A top-tier manufacturer stays updated with these changes, incorporating the latest advancements into their products.

Responsive Customer Support

After-sales service can be as important as the product itself. A reliable manufacturer provides comprehensive customer support, ensuring that clients can reach out for assistance, spare parts, or maintenance inquiries whenever required.

Safety First

Safety should never be compromised. A dedicated manufacturer will ensure that their hydraulic presses meet or exceed all safety standards, integrating features that protect operators and machinery alike.

Customization Capabilities

Every industry and application has its unique requirements. The best hydraulic press manufacturers can tailor their products to meet specific customer needs, whether that means adjusting sizes, pressures, or functionalities.

Transparent Pricing

Reliability isn’t just about the product—it’s also about the business practices. A trustworthy manufacturer will offer transparent pricing, without hidden costs or unexpected fees.

Positive Client Testimonials

Nothing speaks more about a manufacturer’s reliability than the words of satisfied clients. Check for testimonials, reviews, or case studies that highlight the manufacturer’s commitment to quality and customer satisfaction.

Check out www.blyhydraulicpress.com for some of the best hydraulic machines. The manufacturer has a range of products to select from.